Circular Knittiing Machine Needles Manufacture - Lubrication System – Morton

Circular Knittiing Machine Needles Manufacture - Lubrication System – Morton Detail:

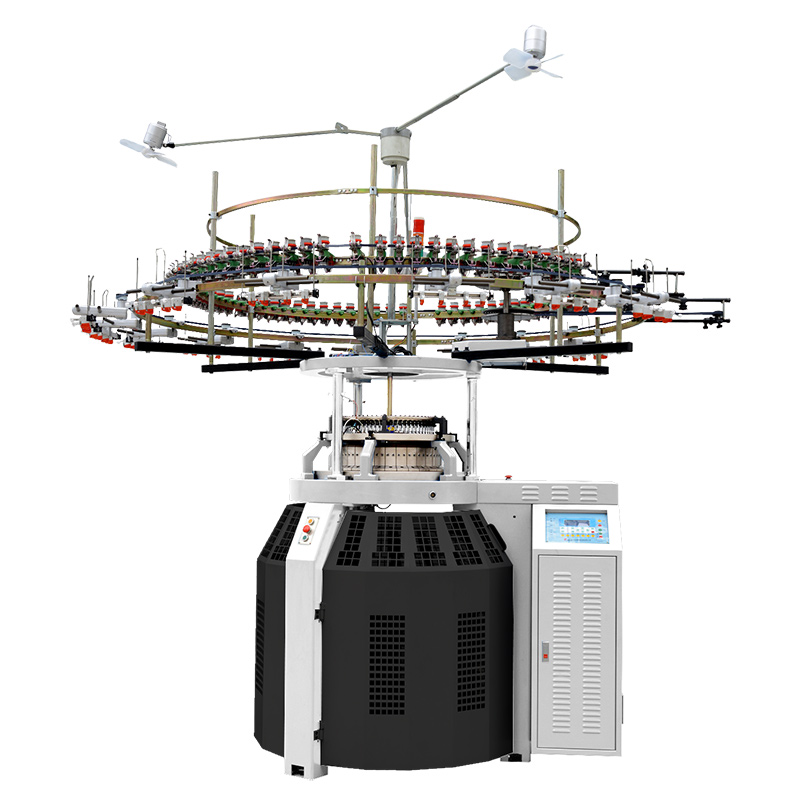

Main features

Even oil distribution over entire circumference of cylinder-no streaking due to excess oil

Individually adjustable lubrication of all needles etc

Low oil consumption due to precise supply of oil to lubricating points

TIPS OF USING AIR PRESSURE OILER:

1. Please dont’ let the oil level exceed the red sign,the amount of oil will be uncontrolled.

2. When the oil tank pressure is in the green zone,the oiler spraying effect is the best.

3 .The using number of oil nozzles should not be less then 12 pcs.

4. Please don’t mix different brand of oil.

5. Please clean the bottom of oil tank at least one time per year.

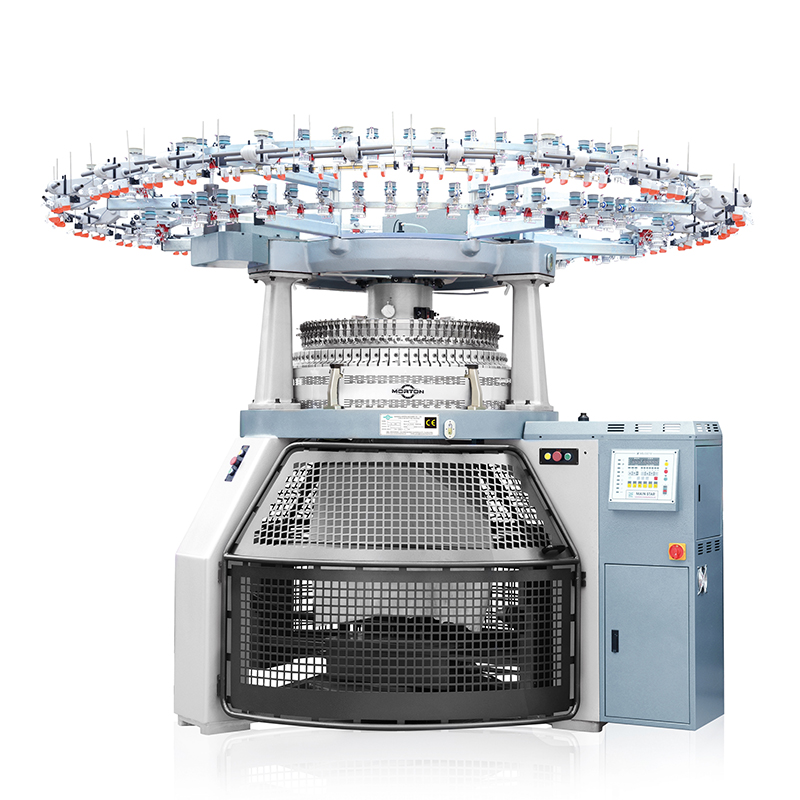

WR3052 FEATURES

The oil circuit is equipped with 12 pulse lubrication pipes.(Optionally add 1-8 spray lubrication points)

Each lubrication pipe can be separately filled with oil in a pulssed way, for more even lubrication and less fuel consumption.

Each lubrication pipe can be individually set oil volume,suitable for oil volumeprecise control of the different needle point of one machine .

The oiler can automatically calculate the best oil injection volume according to the speed of the machine.

More abnormal alarm functions to better protect the needle, sinker and cylinder.

No need to use high-pressure gas drive, no oil mist harmful to human health.

Product detail pictures:

Related Product Guide:

We now have our individual sales group, layout team, technical team, QC crew and package group. Now we have strict high-quality control procedures for each procedure. Also, all of our workers are experienced in printing discipline for Circular Knittiing Machine Needles Manufacture - Lubrication System – Morton , The product will supply to all over the world, such as: Egypt, UK, Pakistan, It is our customers' satisfaction over our products and services that always inspires us to do better in this business. We build mutually beneficial relationship with our clients by giving them large selection of premium car parts at marked down prices. We offer wholesale prices on all our quality parts so you are guaranteed greater savings.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!