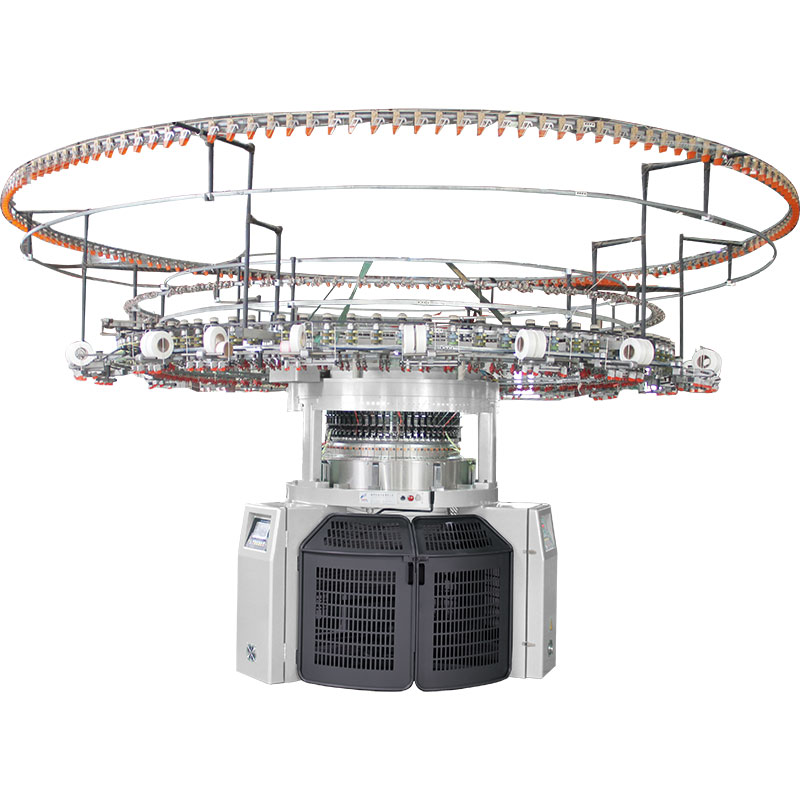

Circular Knitting Machine Factory - Reverse Terry Knitting Machine – Morton

Circular Knitting Machine Factory - Reverse Terry Knitting Machine – Morton Detail:

| MODEL | DIAMETER | GAUGE | FEEDER |

| MT-RT2.0 | 30″-38″ | 16G–24G | 60F-76F |

Machine Features:

1. Suspended Wire Race Bearing Design enable the machine improving running precision and ruducing impact resistance.

At the same time, the drive energy consumption is greatly reduced.

2. Using aircraft aluminum aolly on main part of machine to improve heat dissipation performance and reduce force deformation of the cam box.

3. One Stitch Adjustment to replace the visual error of the human eye with machining accuracy, and the accurate scale display with the high-precision Archimedean adjustment makes the replication process of the same cloth on different machines simple and easy.

4. Unique machine body structure design breaks through traditional thinking and improves machine stability.

5. With central stitch system, higher accuracy, simpler structure, more convenient operation.

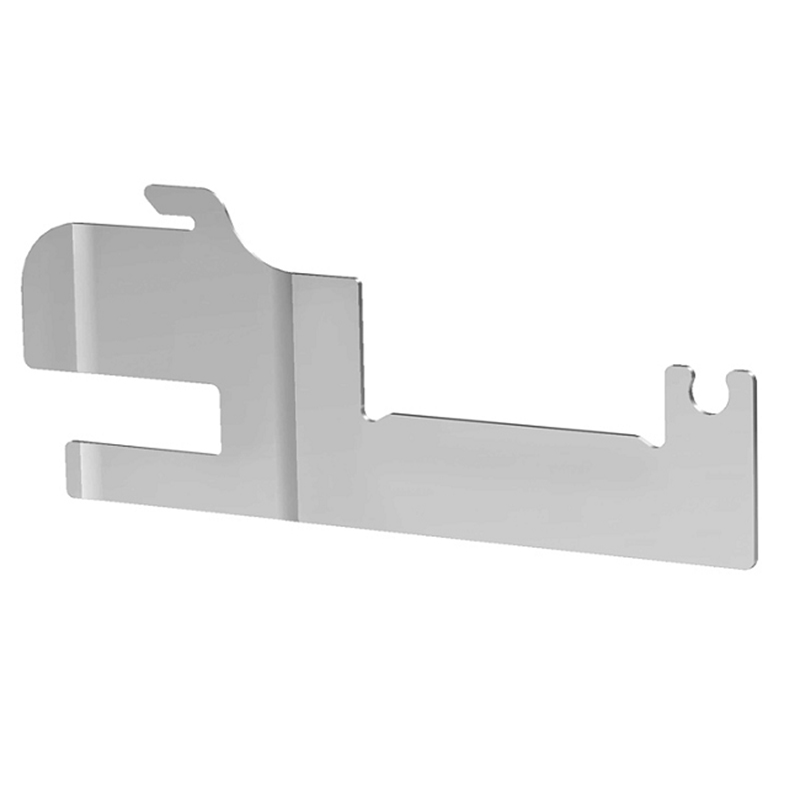

6. New sinker plate fixing design,eliminating deformation of sinker plate.

Product detail pictures:

Related Product Guide:

Our corporation has been specializing in brand strategy. Customers' gratification is our greatest advertising. We also source OEM company for Circular Knitting Machine Factory - Reverse Terry Knitting Machine – Morton , The product will supply to all over the world, such as: Paraguay, Monaco, Florence, Customer satisfaction is our first goal. Our mission is to pursue the superlative quality, making continual progress. We sincerely welcome you to make progress hand in hand with us, and construct a prosperous future together.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.