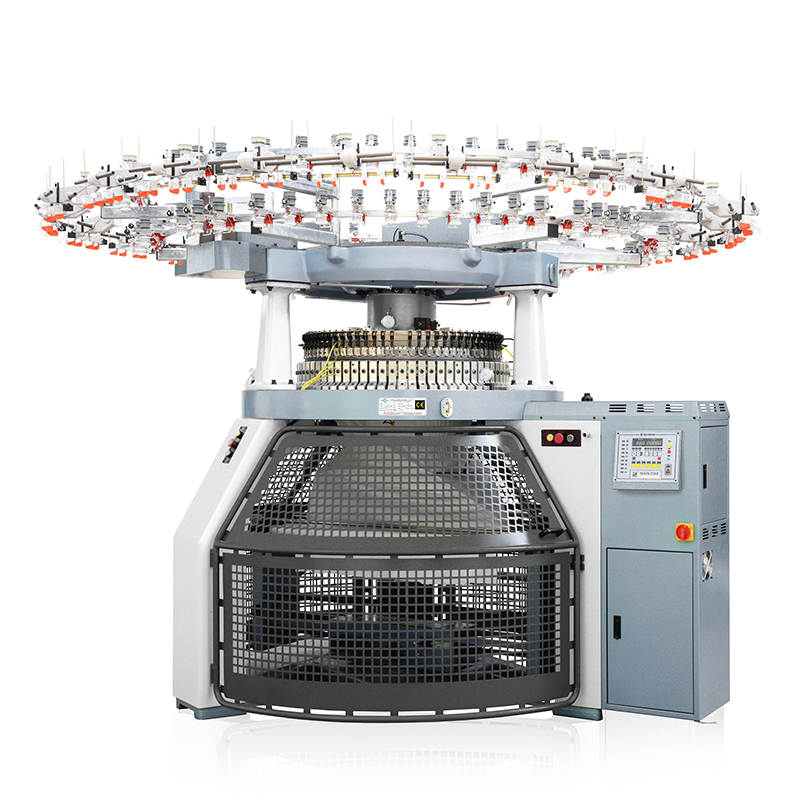

Rib Circular Knitting Machine

| MODEL | DIAMETER | GAUGE | FEEDER |

| MT-EC-RB2.1 | 26"-42" | 18G--46G | 56F-88F |

Machine Features:

1. Suspended Wire Race Bearing Design enables the machine to run with high stability and precision.

2. Using aircraft aluminum aolly on main part of machine to improve heat dissipation performance.

3. One Stitch Adjustment to replace the visual error of the human eye with machining accuracy, and the accurate scale display with the high-precision Archimedean adjustment makes the replication process of the same cloth on different machines simple and easy.

4. Unique machine body structure design breaks through traditional thinking and improves machine stability.

5. With central stitch system, higher accuracy, simpler structure, more convenient operation.

6. Double Jersey Machine adopts a double shaft linkage structure, which can effectively eliminate the running idle caused by the gear backlash.

7. Separation of the needle distance adjustment and the transmission part of the interlock machine avoids affecting the stability of the transmission when adjusting the needle distance.

video