Guidance

Knitted fabrics can be divided into single-sided knitted fabrics and double-sided knitted fabrics.Single jersey: A fabric knitted with a single needle bed.Double jersey: A fabric knitted with a double needle bed.The single and double sides of the knitted fabric depend on the weaving method.

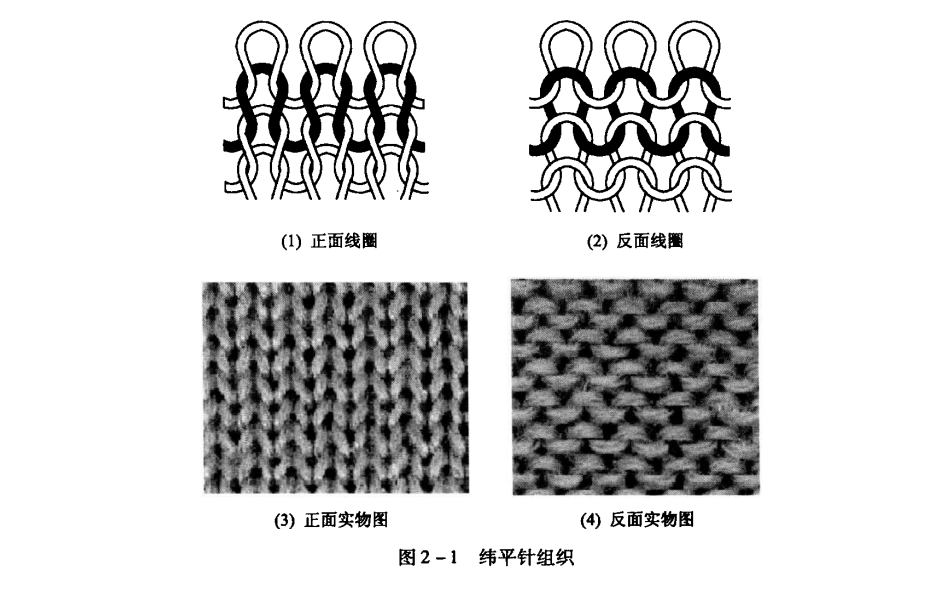

1. Weft Circular plain needle organization

The weft circular plain stitch structure is formed by successively stringing the same unit coils in one direction. The two sides of the weft circular plain stitch structure have different geometric shapes. The loop column on the front stitch and the stitch wale are arranged at a certain angle. The knots and neps on the yarn are easily blocked by the old loops and stay on the reverse side of the knitted fabric. , so the front is generally smoother and smoother. The circle arc on the reverse side is arranged in the same direction as the coil row, which has a large diffuse reflection effect on the light, so it is relatively dark.

The weft circular plain knitted fabric has a smooth surface, clear lines, fine texture and smooth hand feel. It has good extensibility in transverse and longitudinal stretching, and the transverse extensibility is greater than that in the longitudinal direction. Moisture absorption and air permeability are good, but there are detachability and curling properties, and sometimes the coil is skewed. Commonly used in the production of underwear, T-shirt fabrics and so on.

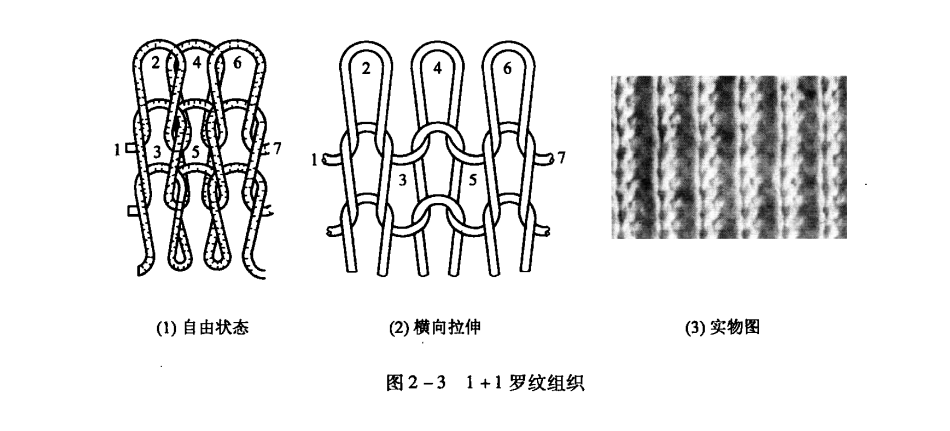

2. Rib knitting

The rib structure is made up of the front stitch wale and the reverse stitch wale arranged alternately with a certain combination rule. The front and back stitches of the rib structure are not on the same plane, and the stitches on each side are adjacent to each other. There are many types of rib structures, which vary depending on the number of wales on the front and back. Usually, numbers are used to represent the combination of the number of wales on the front and back, such as 1+1 rib, 2+2 rib or 5+3 rib, etc., which can form different appearance styles and styles. Performance ribbed fabric.

The rib structure has good elasticity and extensibility in both longitudinal and transverse directions, and the transverse extensibility is greater than that in the longitudinal direction. Rib weave can only be released in the opposite direction of weaving. In the rib structure with the same number of wales on the front and back, such as 1+1 rib, the curling force does not appear because the forces that cause curling are balanced with each other. It is commonly used in the production of close-fitting elastic underwear, casual clothing, swimwear and pants fabrics, as well as elastic parts such as necklines, trousers, and cuffs.

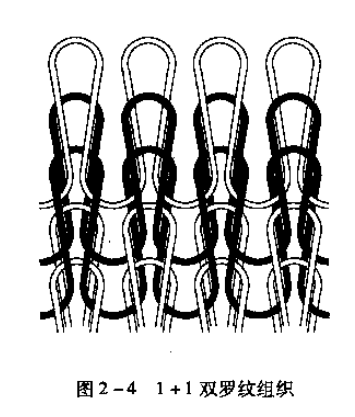

3. Double rib organization

The double rib organization is commonly known as the cotton wool organization, which is composed of two rib organizations combined with each other. The double rib knitting presents front loops on both sides.

The extensibility and elasticity of the double rib structure are smaller than that of the rib structure, and at the same time, only the reversible weaving direction is released. When an individual coil is broken, it is hindered by another rib structure coil, so the detachment is small, the cloth surface is flat, and there is no curling. According to the weaving characteristics of the double rib weave, various color effects and various longitudinal concave-convex stripes can be obtained by using different colored yarns and different methods on the machine. Commonly used in the production of intimate underwear, sportswear, casual clothing fabrics, etc.

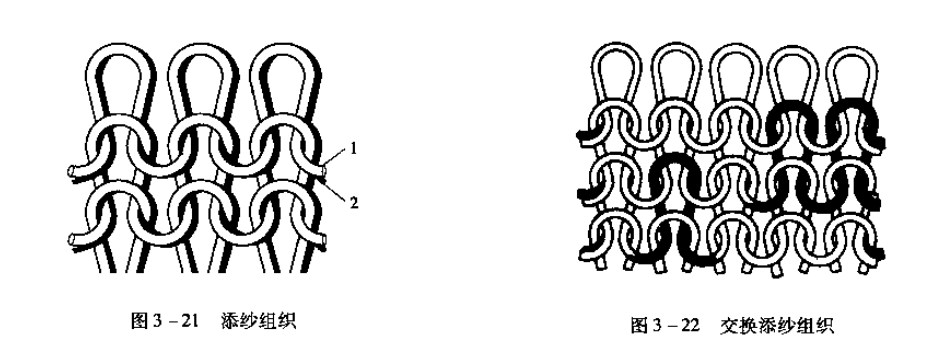

4. Plating organization

The plated weave is a weave formed by two or more yarns in part or all of the loops of the pointer fabric. Plating structure generally uses two yarns for weaving, so when two yarns with different twist directions are used for weaving, it can not only eliminate the skew phenomenon of circular knitted fabrics, but also make the thickness of the knitted fabrics uniform. Plating weave can be divided into two categories: plain plating weave and color plating weave.

All loops of plain plated weave are formed by two or more yarns, where the veil is often on the front side of the fabric and the ground yarn is on the back side of the fabric. The front side shows the circle column of the veil, and the reverse side shows the circle arc of the ground yarn. The compactness of the plain plated weave is larger than that of the weft plain stitch, and the extensibility and dispersal of the plain stitch are smaller than that of the weft plain stitch. Commonly used in the production of underwear, sportswear, casual clothing fabrics, etc.

Post time: May-30-2022