1. Quality requirements of circular knitting needles

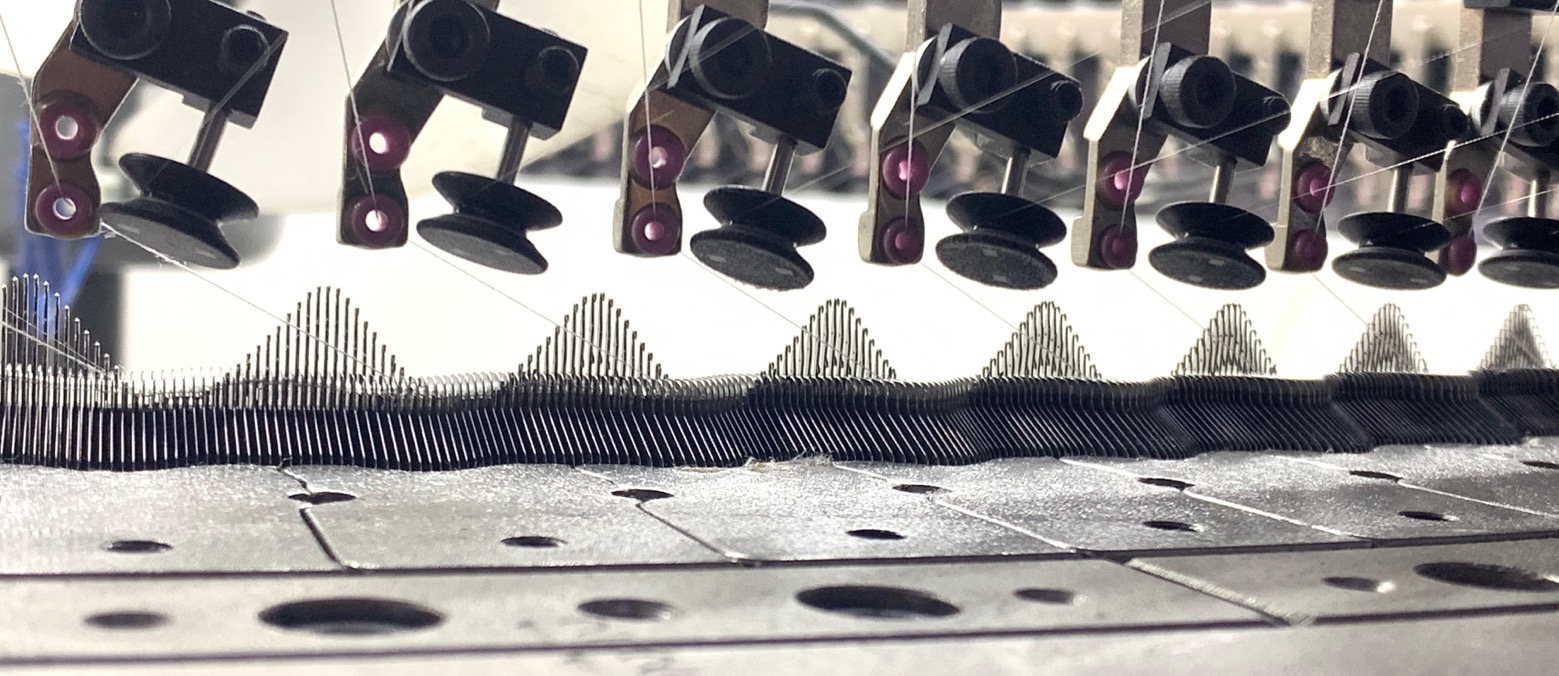

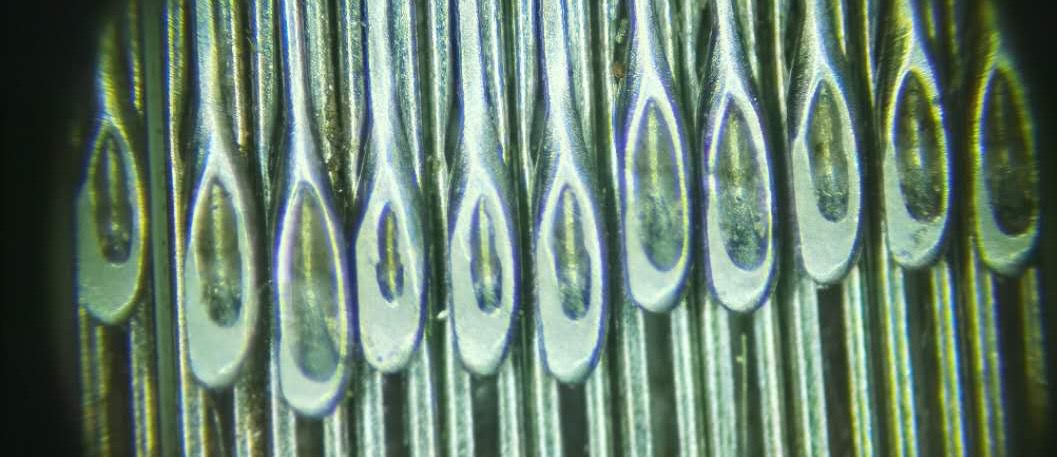

1) Consistency of knitting needles.

(A) The consistency of the front and back and left and right of the needle body side by side of the knitting needles

(B) the consistency of the hook size

(C) the consistency of the distance from the stitch to the end of the hook

(D) the length of the gadolinium tongue and the opening and closing state consistency.

2) The smoothness of the needle surface and the needle groove.

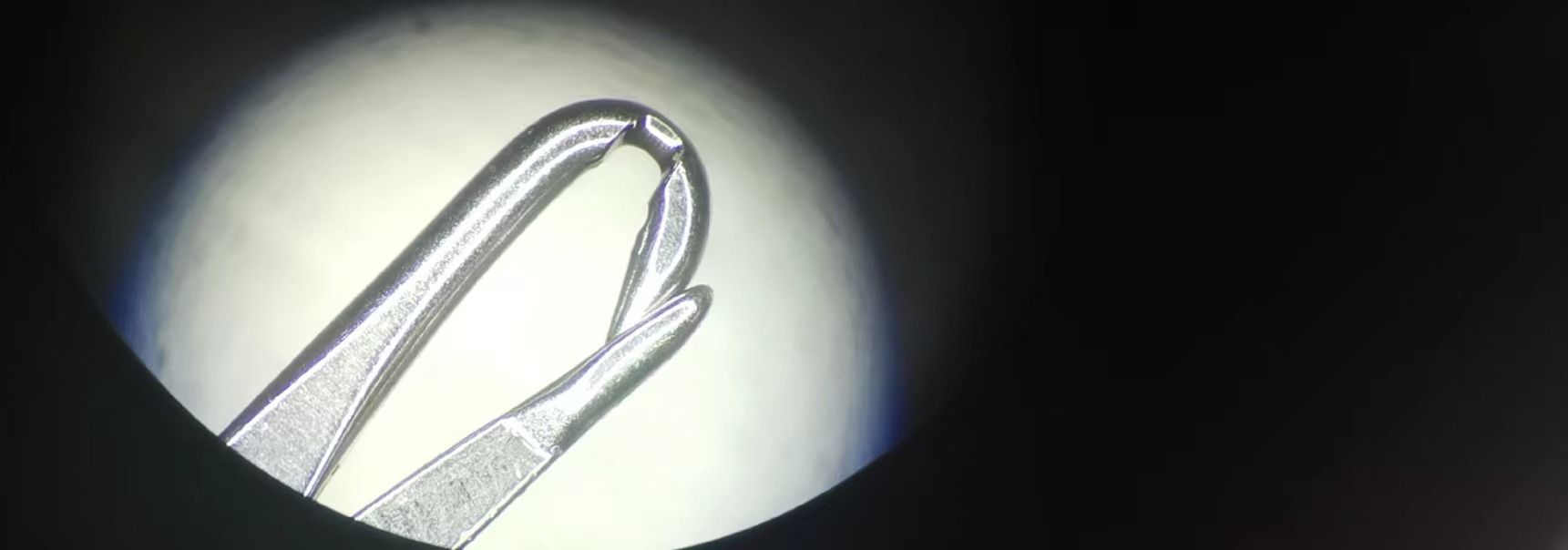

(A) The position of the knitting needle involved in the knitting needs to be rounded, and the surface is polished smoothly.

(B) The edge of the needle tongue should not be too sharp, and needs to be rounded and smooth.

(C) The inner wall of the needle groove should not be too obvious, try Reduce the height tolerance of the inner wall due to process problems, and the surface treatment is smooth.

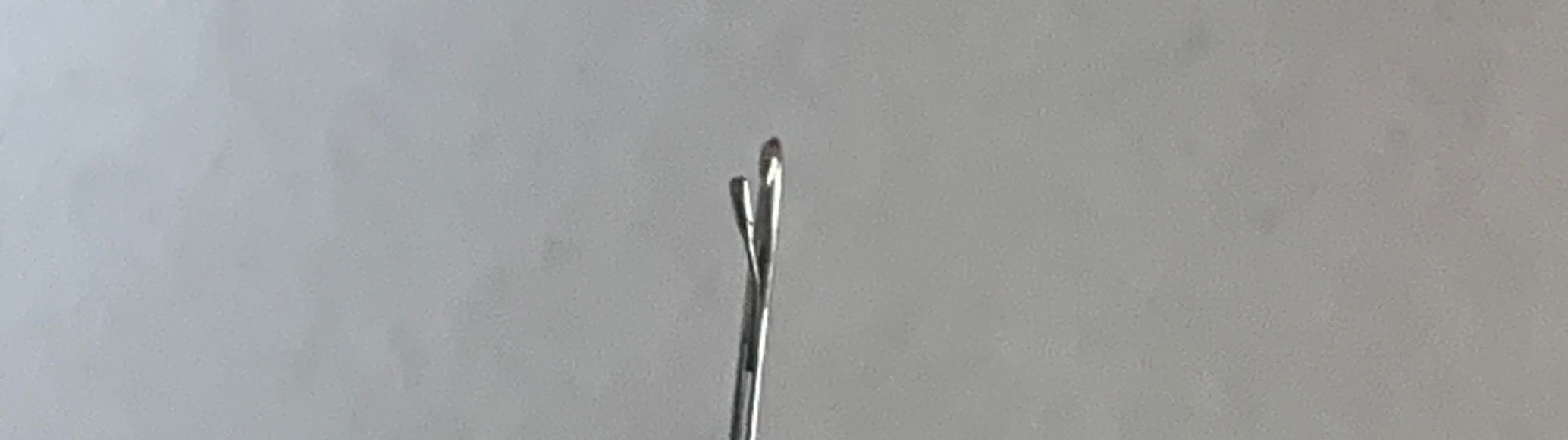

3) The flexibility of the needle tongue.

The needle tongue needs to be able to open and close flexibly, but the lateral swing of the needle tongue cannot be too large.

4) The hardness of the knitting needle.

The hardness control of knitting needles is actually a double-edged sword. If the hardness is high, the knitting needle will appear too brittle, and it is easy to break the hook or the needle tongue; if the hardness is low, it is easy to swell the hook or the service life of the knitting needle is not long.

5) The degree of anastomosis between the closed state of the needle tongue and the hook of the needle.

2. Causes of common problems with knitting needles

1) Crochet hook wear

(A) The reason for the production of raw materials for knitting. Darker colored yarn-dyed yarns, steamed yarns, and dust pollution during yarn storage may all cause this problem.

(B) The yarn feed tension is too large

(C) The length of the fabric is longer, and the yarn bending stroke is larger when weaving.

(D) There is a problem with the material or heat treatment of the knitting needle itself.

2) The needle tongue is broken in half

(A) The fabric is denser and the thread length is shorter, and the needle tongue is stressed excessively when the loop is unlooped during the knitting process.

(B) The pulling force of the cloth winder is too large.

(C) The running speed of the machine is too fast.

D) The process is unreasonable during the processing of the needle tongue.

(E) There is a problem with the material of the knitting needle or the hardness of the knitting needle is too high.

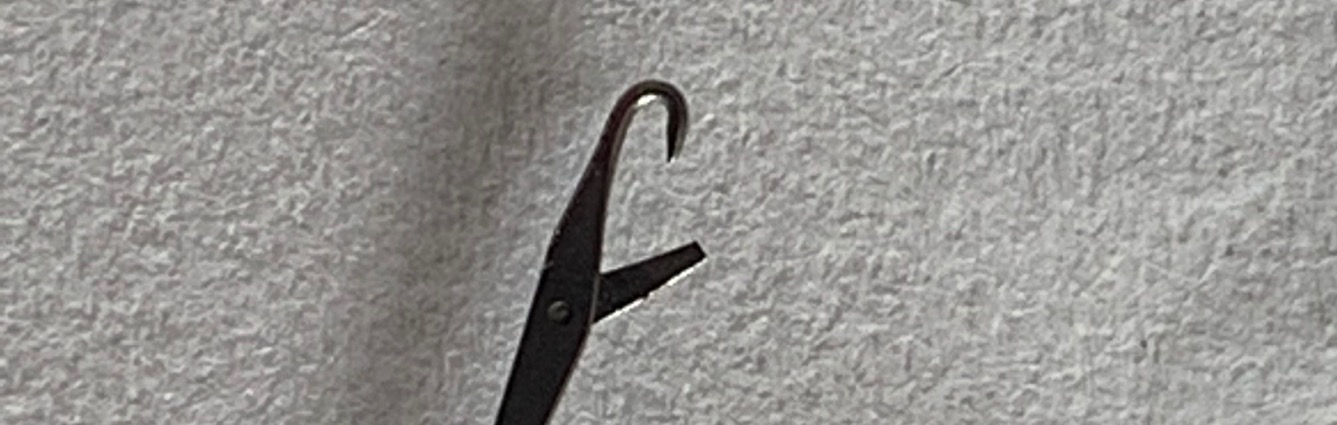

3) Crooked needle tongue

(A) There is a problem with the installation position of the yarn feeder

(B) There is a problem with the yarn feed angle

(C) Yarn feeder or needle tongue is magnetic

(D) There is a problem with the angle of the air nozzle for dust removal.

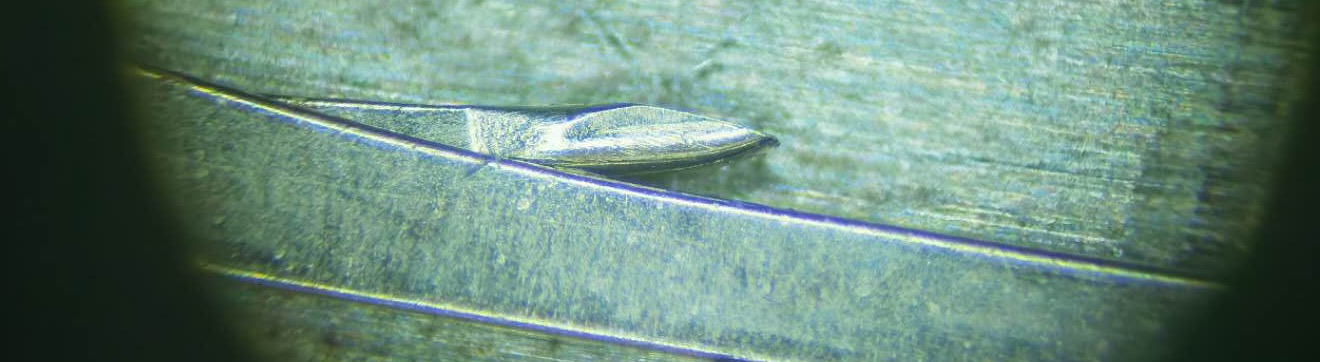

4) Wear on the front of the needle spoon

(A) The yarn feeder is pressed against the knitting needle, and it is directly worn to the needle tongue.

(B) The yarn feeder or knitting needle is magnetic.

(C) The use of special yarns may wear the needle tongue even when the length of the knitting thread is short. But the worn parts will show a more rounded state.

This article transcrript from Wechat subscription Knitting E Home

Post time: Jul-07-2021