Advanced customization is a high-end service tailored to individual needs.

The textile industry has developed to this day. If ordinary-sized enterprises want to gain a foothold in the market, it is difficult for them to develop in a large and comprehensive way. They must go to a certain segmented field to achieve the ultimate goal and pursue small but beautiful.

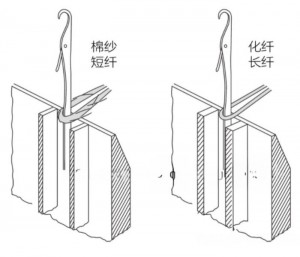

Let’s take a simple example. In circular knitting machine design,short-fiber cylinders and long-fiber cylinders have different designs. For short fibers such as cotton yarn, the gap between the needle mouth and mouth should be designed to be larger. Because cotton yarn is relatively fluffy, if the gap between the mouth and mouth is too small, it will easily get stuck, causing needle paths and shortening the cleaning time. However, the opposite is true for chemical fiber, and the gap should be small. Because chemical fiber is not easy to get stuck, but the cloth surface is more sensitive. If the gap is too large, the swing range of the knitting needle will be too large, which will easily affect the needle path on the cloth surface. So what if you have to make two kinds of yarns? You can only take the middle value and take care of each one. (The picture magnifies the spacing difference for visualization)

Including the design of the cleaning system, the equipment for producing cotton yarn and chemical fiber also has many detailed design differences. The advantages and disadvantages of using small needles and large needles, long needle latches and short needle latches, etc., will not be discussed one by one here.

Even if it is the same chemical fiber, it has differentiated designs based on the different characteristics of the yarn.

For example, DTY and FDY have different ductility. On machines with high-density needles, slight differences in yarn tension will lead to very different cloth surface effects. Therefore, to produce yarns with different elasticities, different triangular curve designs need to be used to achieve the best cloth surface effect.

Of course, there will definitely be customers who feel that this operation becomes complicated. It would be best to have a universal triangle that can be made with various raw materials. Of course, the same type of triangle can also be produced, but when customers require the ultimate effect, they must be precise. Only with personalized customization can we achieve the best results.

Therefore, when purchasing machines, you should first consider the positioning and development direction of your company. Only through full communication can you choose the equipment that is most suitable for the development of your business and avoid detours!

Post time: Jan-30-2024