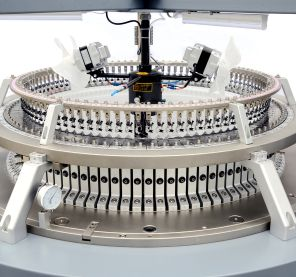

Lubrication mechanism and oil supply amount of knitting needles

The knitting oil is fully mixed with the compressed air to form oil mist before entering the cam channel. The formed oil mist spreads rapidly after entering the cam path, forming a uniform oil film on the cam path and the surface of the knitting needle, thereby producing lubrication.

Knitting oil atomization

The atomization of needle oil first requires the compressed air and needle oil to be fully mixed. This process is mainly completed within the fuel tank. If some accessories in the oil tank are damaged, blocked or have insufficient air supply, the mixing effect of oil and air will be affected, thereby affecting the lubrication effect of the oil. After the oil and gas are fully mixed and enter the oil pipe, the oil and gas will be temporarily separated due to the pressure drop, but the oil and gas passing through the pores of the oil nozzle will be re-pressurized to form oil mist . The formed oil mist will quickly and evenly disperse after leaving the oil nozzle. Covers the triangular needle path and the surface of knitting needles to form an oil film, thereby reducing friction and vibration, so that the life and performance of knitting needles can be improved accordingly.

Atomization effect check

If the oil-gas ratio is uncoordinated, the atomization effect of the needle oil will be reduced accordingly, thus affecting the lubrication performance of the needle oil. Due to the influence of factors such as equipment and detection conditions, the atomization effect of needle oil cannot be quantitatively detected and can only be observed qualitatively. The observation method is: unplug a grease nozzle when the power is on, tilt the grease nozzle to about 1cm away from the surface of the machine or the palm of your hand, and observe for about 5 seconds. It proves that the current oil-gas mixing ratio is appropriate; if oil droplets are found, it means that the oil supply volume is too large or the air supply volume is too small; if there is no oil film, it means that the oil supply volume is too small or the air supply volume is too large. Adjust accordingly.

About fuel supply

The oil supply amount of the knitting machine actually refers to the oil and air mixing amount of the treadmill that is evenly mixed and can produce the best atomization effect. When adjusting, attention should be paid to adjusting the oil volume and air volume at the same time, rather than simply adjusting one of the oil volume or the air volume. Doing so will reduce the atomization effect, fail to achieve the required lubrication, or produce oil needles. And the triangular needle track is worn. After adjusting the oil supply, you need to check the atomization of the needle oil again to ensure the best lubrication effect.

Determination of fuel supply

The amount of oil supply is related to factors such as machine speed, starting modulus, yarn linear density, cloth type, raw materials and the cleanliness of the weaving system. In an air-conditioned workshop, a reasonable amount of oil supply will minimize the heat generated by the machine operation and will not form bright oil needles on the cloth surface. Therefore, after 24 hours of normal operation, the surface of the machine is generally only warm and not hot, otherwise it means that the oil supply is too low or some parts of the machine have not been adjusted properly; when the oil supply is adjusted to the maximum, the surface of the machine is still very hot. , indicating that the machine is dirty or running too fast.

Post time: Apr-29-2024