(1)First of all, the blind pursuit of high output means that the machine has single performance and poor adaptability, and even with the decline of product quality and the increase of defect risk. Once the market changes, the machine can only be handled at a low price.

Why is it often impossible to have both output, performance and quality? We all know that there are two ways to increase production: faster speed and higher number of feeders. Obviously, increasing the number of feeders seems to be easier to achieve.

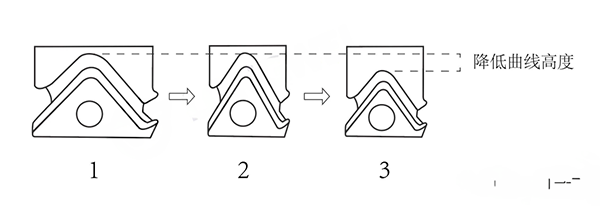

However, what will happen if there is an increase in the number of feeders? As shown in the following picture:

After the number of feeders increases, the width of the cam narrows and the curve becomes steep . If the curve is too steep, the needles will cause serious wear, so the height of the curve must be lowered to make the curve smooth.

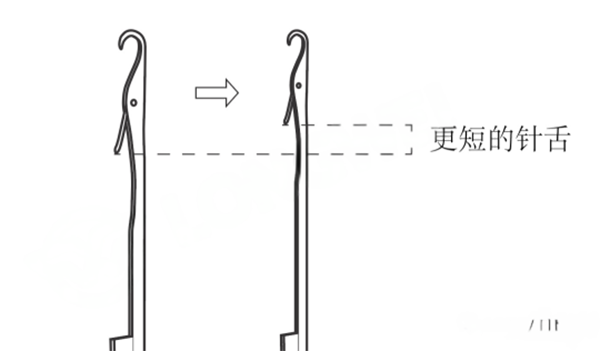

After the curve is lowered, the height of the needle becomes lower, and the long needle latch knitting needle coil cannot completely retreat, so the machine can only use the knitting needle of the short needle latch.

Even so, the space that can be reduced is limited.Therefore, the corner curve of the high feeder machine is always relatively steep. This means that the wear speed of the stitches will also be faster.

The needle with short needle latch will become more difficult to operate when producing cotton yarn and adding lycra .

Due to the narrow corner curve and the smaller space of the gauze nozzle, it is more difficult for the machine to adjust the time position. Various factors lead to the single use of the machine with a high number of feeders and poor adaptability.

(2)High feeder numbers and high production do not bring high profits.

The higher the number of feeders, the greater the resistance of the machine, the higher the power consumption. Everyone understands the law of energy conservation.

The higher the number of feeders, the higher the machine runs in the same circle, the more the opening and closing times of the needle latch, the faster the frequency, and the shorter the life of the needle. And it tests the quality of knitting needles.

The higher the frequency of needle opening and closing, the greater the probability of unstable factors on the cloth surface, and the higher the risk.

For example: 96-feeders machines run a circle of needle latch opening and closing 96 times, 15 turns per minute, 24 hours opening and closing times: 96*15*60*24=2073600 times.

The 158-feeders machine runs a circle of needle latch opening and closing 158 times, 15 turns per minute, 24 hours opening and closing times: 158*15*60*24=3412800 times.

Therefore, the use time of knitting needles is shortened year-on-year.

(3)Similarly, the resistance and friction of the cylinder are also greater, and the folding speed of the whole machine is also faster.

In this case, if the processing fee is calculated by time or rotation, there must be a corresponding multiple processing fee to offset these losses. In fact, if it is not a very urgent order, the processing fee often cannot reach the same price as the number of feeders.

The real high yield that should be pursued comes from higher machine accuracy and precision and more reasonable design. Make the machine more energy-efficient when running, make the performance more stable and reliable, and make the wear and friction less to obtain a longer service life of the knitting needle. Better fabric quality and reduce unnecessary losses.

Post time: Jan-19-2024